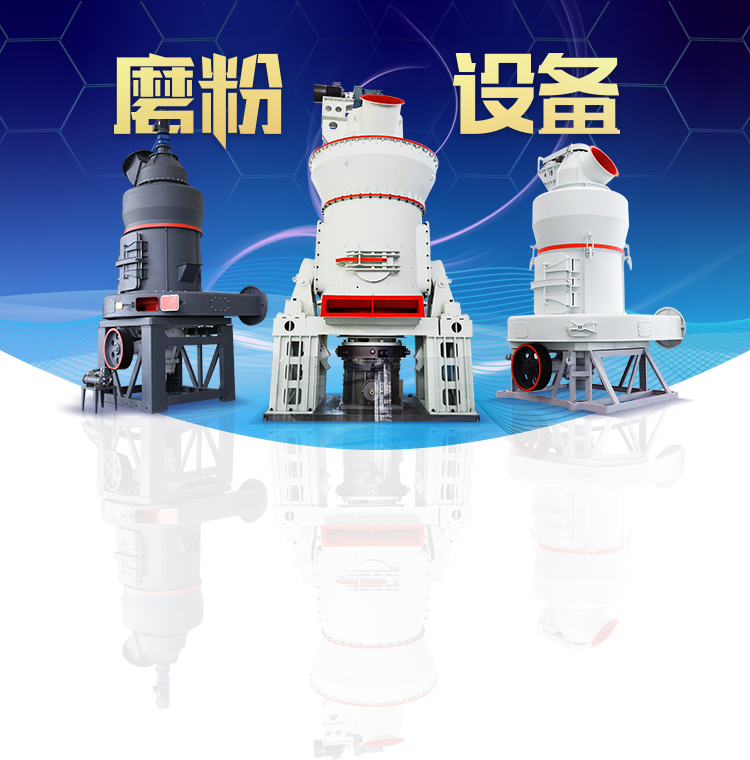

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Pneumati滑石 Roll Mining Mill Working Princle

"Working principle and application of roller mill"

2024年3月13日 The roller mill is a type of powder making equipment that combines ring roller grinding with air flow screening and pneumatic conveying It has the characteristics of strong In the grinding system, the pneumatic roller mill simultaneously performs the functions of crushing, cutting and pressing the grain As part of the mill complex, the pneumatic roller mill is located in the grinding department and mainly on Pneumatic Grinding Mill (working Principle)2023年7月4日 Working principle: the motor drives the grinding table to rotate through the reducer, the material falls into the center of the grinding table from the feed inlet through the Roller Mill Springer2015年3月9日 Working principle of vertical roller mill is driven by motor reducer rotating disc, and the hot air from the air inlet into the vertical mill, the material from the feed opening falls on The working principle of vertical roller mill CSDN博客

.jpg)

Roller mill Working principle and performance advantages

2024年3月8日 The roller mill is a kind of ring rolling mill combined with airflow screen pneumatic conveying form of the milling equipment It is a versatile milling equipment It must have dry Roller Mill Working Principle: High pressure hanging roller mill mainframe, roll grinding hanger on fastening a 10001500 kg pressure spring After starting work, grinding rolls around spindle rotation and high pressure spring and centrifugal Roller Mill Working Principle Liming Heavy 2020年11月11日 two components: the roll gap size and roll alignment The roller mill operator can control the particle size by widening or narrowing the roll gap For most roller mills, the Roller mills: Precisely reducing particle size with greater The working part of the highpressure roller mill is a pair of highpressure rolls arranged in parallel and facing each other Each roller is driven by a motor through a planetary gear reducer, High pressure roller mill working principle and industry use

Pneumatic Systems in the Mill IAOM MEA

2022年3月31日 Pneumatic conveying is quite simple – pneumatic systems are NOT This presentation is not designed to teach you how to design a system, but to understand how one Rolling is a process in which the material is drawn with the action of friction between two rotating cylindrical rolls that helps reduce the thickness of the material In this process, the two cylindrical rollers are attached with bearings Rolling of Metals in Mills: Definition, Types, 2006年10月1日 Fig 1 shows a fourhigh rolling mill with work roll shifting When work roll is considered, the thrust force includes the following two parts as shown in Fig 2: (1) F AWS thrust force is the resultant force of the friction force along the shifting direction of the deformation zone between the work roll and the strip (2) F AWB thrust force is the resultant force of the friction Analysis of thrust force in a work roll shifting mill2023年12月27日 Working The last two rollers are adjusted so that the distance between them is less than between the first two rollers The first roller is the receiving roller, which rotates at a speed slower than the second roller, which Triple Roller Mill: Principle, Construction, Working

Rod Mill, Rod Mill Manufacturers, Rod Mill

(1) Rod mill is usually selected in order to prevent overgrinding in gravity or magnetic separation plant of tungsten tin and other rare metals mine; (2) In two stages grinding, the capacity of rod mill in the first stage grinding is larger than 2019年7月28日 A dynamic model of the cold rolling process at a continuous rolling mill combining the model of the electromechanical system and that of the deformation zone has been developedIMPROVEMENT OF OPERATIONAL EFFICIENCY OF COLD ROLLING MILL WORK ROLLS2021年4月19日 Published in MATERIA 2021;23:6366 The idea of minetomill optimization has been tested in various mines in last decades, resulting in higher mill throughput in many mines, but also (PDF) Feasibility and necessity of mine to mill ResearchGateSendizmer roll mill: Sendizmer is a clustered form of roll arrangement used to produce thin foils and sheets With this arrangement, strong metals can be rolled with ease With this process, we can attain an optimally high reduction ratio Planetary roll mill: These roll mills are equipped with tiny rolls that are present along the circumferenceRolling of Metals in Mills: Definition, Types, Working, Applications

Pneumatic System: Definition, Components, Working,

2022年10月1日 The Hydraulic system uses oil as the working fluid This is an openloop system This is a closedloop system The construction of pneumatic systems is simple 3 Reasons Why Engineering is Essential to the Mining Industry April 29, 2022 Manufacturing Technology What is Forming? Types of Forming Process [Notes PDF] February 26, 2022Write better code with AI Code review Manage code changessbm/sbm roll mining mill operation principlesmd at mainWorking Principle of Ball mill Ball mill is an efficient tool for grinding various materials into powder It is widely applied in cement industry, chemical industry, new building materials, fireresistant materials, fertilizer, porcelain and glass industry, etc Working Principle of Ball mill The ball mill runs along the outside gearworking princle of ball mill restaurantmediterranee2019年5月26日 1) A finishing mill work roll in a steel plant failed after 2766 tonnage, 3 months before its expected 12 month life It broke at the neck near the bearings 2) Metallurgical analysis found the roll failed in brittle fracture mode 429719 (Finishing Mill Work Roll, HSM) PDF

.jpg)

Ribbon Fatigue Spalling of a Forged Work Roll

2014年10月31日 Catastrophic failure of a forged work roll used in a cold rolling mill was investigated The spalled roll showed fatigue arrest marks in a smooth continuous path along the circumferential directionYou've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activitysbm/sbm working princle of ball millmd at master sbm2024年3月16日 Jetmillworkingprinciple Free download as PDF File (pdf), Text File (txt) or read online for free Jet mills use high pressure air or steam to micronize materials without heat or moving parts The material is fed into a cylindrical chamber with tangential jets that cause particles to collide and reduce in size down to less than 10 micronsJet Mill Working Principle PDF Jet Engine Mill (Grinding)2023年7月19日 These rolls rotate in opposite directions and at varying speeds relative to each other This movement allows the mill to mix, refine, disperse, or homogenize viscous materials Related: Silverson Mixer Working Mechanism of the Triple Roller Mill: As the material enters the hopper, it proceeds between rollers 1 and 2, while processing size Triple Roller Mill: Principle, Construction, Diagram, Working,

Ball Mill Grinding Machines: Working Principle, Types, Parts

Ball Mill, Working Principle, Types, Parts, Applications and Advantages and exploring alternative grinding technologies, such as stirred media mills and highpressure grinding rolls (HPGR), as alternatives to traditional ball mills mining, pharmaceuticals, chemicals, ceramics, and more By leveraging the advantages of ball mills and 1997年11月1日 The Coolflex offline computer model has been developed for analysis of work roll thermal conditions in hot strip mills and can be used to simulate and predict work roll thermal profile Various effects of the rolling and cooling parameters on the transient work roll thermal profile in both continuous and reversing finishing (Steckel) hot strip mills are investigatedApplication of Coolflex model for analysis of work roll 2022年10月17日 Low speed: At low speed, the mass of balls will slide or roll up one over another and will not produce a significant amount of size reduction High Speed: At highspeed balls are thrown to the cylinder wall due to centrifugal force and no grinding will occur Normal speed: At Normal speed balls are carried almost to the top of the mill and then fall into a Ball Mill; Principle, Working, and Construction » Pharmaguddu2016年1月1日 Model of generating working roll failures The design life of working rolls of any finishing stand at the sheet mill may be determined for an estimated rolling sequence of the j th strip batches with due regard to their shape accuracy and based on the general methodological approach to assessment of parameter reliability of process facilities [1 Analytical Model for the WideStrip Rolling Mills Working Rolls Wear

.jpg)

working principle是什么意思working principle的翻译音标

爱词霸权威在线词典,为您提供working principle的中文意思,working principle的用法讲解,working principle的读音,working principle的同义词,working principle的反义词,working principle的例句等英语服务。1988年12月1日 Currently, work roll shifting mill is the most effective mill for strip shape control [12,13] because it improves the strip crown accuracy and edge phenomenon, (PDF) Characteristics of Rolling Mills with Roll 2016年6月3日 Therefore, its foundation can be a concrete floor slab designed for dead load only, whereas a cylindrical ball mill requires a reinforced concrete submat with a minimum of two times the mass of the rotating parts Regrind Tower Mill Operating Work Index 911MetallurgistTwo alloys grades for work rolls used in the roughing stand of Hot Strip Mill (HSM) are compared The first grade known as High Chromium Steel (HCS) is presently the most widely used alloy for Dominant roughing mill work roll grades in the world

Monitoring ore loss and dilution for minetomill integration

2016年2月1日 The purpose of this study is to understand how ore loss and dilution affect the mine call factor, with the aim of subsequently improving the quality of ore mined and fed to the millworking princle of ball mill Working Principle Of Ball Mill Pdf File Ball Mill Working Principle Gipserebide Ball mill working principle and main parts ball mill working principle to be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to working princle of ball mill kordeusz2024年9月19日 The working principle of the mining ball mill is that the abrasives and media in the cylinder are impacted and rubbed against each other by inertia and centrifugal force, so that the materials are crushed The filling rate of grinding media in the barrel of a mining ball mill is usually 29% to 30% If the particle size of the feed materials is Mining Ball MillHongji Mining MachineryDOI: 1014288/1 Corpus ID: ; A pilotscale examination of a novel high pressure grinding roll / stirred mill comminution circuit for hardrock mining applicationsA pilotscale examination of a novel high pressure grinding roll

.jpg)

Classification and material selection of rolls rolling mill rolls

2023年7月31日 The finishing mill is called a fourroll mill, and the backup rolls are used to prevent the working rolls from bending due to rolling force Backup rolls generally use cast steel rolls with a hardness of 4050HSD, and some countries use 2023年10月25日 Gold Mining Wet Pan Mill used for the material recrushing after the first crushing The capacity is 150 t/h The maximum feed size is 30 mm and the output size is 007406 mm wet pan mill is particularly suitable for grinding rock gold ore which c [ protected] +86; 0086 ; Home;Sinogomine Industrial Technology Co,LtdGold Mining Wet Pan Mill2006年10月1日 Fig 1 shows a fourhigh rolling mill with work roll shifting When work roll is considered, the thrust force includes the following two parts as shown in Fig 2: (1) F AWS thrust force is the resultant force of the friction force along the shifting direction of the deformation zone between the work roll and the strip (2) F AWB thrust force is the resultant force of the friction Analysis of thrust force in a work roll shifting mill2023年12月27日 Working The last two rollers are adjusted so that the distance between them is less than between the first two rollers The first roller is the receiving roller, which rotates at a speed slower than the second roller, which Triple Roller Mill: Principle, Construction, Working

Rod Mill, Rod Mill Manufacturers, Rod Mill

(1) Rod mill is usually selected in order to prevent overgrinding in gravity or magnetic separation plant of tungsten tin and other rare metals mine; (2) In two stages grinding, the capacity of rod mill in the first stage grinding is larger than 2019年7月28日 A dynamic model of the cold rolling process at a continuous rolling mill combining the model of the electromechanical system and that of the deformation zone has been developedIMPROVEMENT OF OPERATIONAL EFFICIENCY OF COLD ROLLING MILL WORK ROLLS2021年4月19日 Published in MATERIA 2021;23:6366 The idea of minetomill optimization has been tested in various mines in last decades, resulting in higher mill throughput in many mines, but also (PDF) Feasibility and necessity of mine to mill ResearchGateSendizmer roll mill: Sendizmer is a clustered form of roll arrangement used to produce thin foils and sheets With this arrangement, strong metals can be rolled with ease With this process, we can attain an optimally high reduction ratio Planetary roll mill: These roll mills are equipped with tiny rolls that are present along the circumferenceRolling of Metals in Mills: Definition, Types, Working, Applications

Pneumatic System: Definition, Components, Working,

2022年10月1日 The Hydraulic system uses oil as the working fluid This is an openloop system This is a closedloop system The construction of pneumatic systems is simple 3 Reasons Why Engineering is Essential to the Mining Industry April 29, 2022 Manufacturing Technology What is Forming? Types of Forming Process [Notes PDF] February 26, 2022Write better code with AI Code review Manage code changessbm/sbm roll mining mill operation principlesmd at mainWorking Principle of Ball mill Ball mill is an efficient tool for grinding various materials into powder It is widely applied in cement industry, chemical industry, new building materials, fireresistant materials, fertilizer, porcelain and glass industry, etc Working Principle of Ball mill The ball mill runs along the outside gearworking princle of ball mill restaurantmediterranee

白云石粉生产加工流程

--工业磨粉机厂家预粉磨砂粉立磨精品砂粉设备

--文山铁虎矿石磨粉机

--临沧

--碳酸钙制粉设备生产厂家电话

--mtw欧版磨构造

--打桩机限位器

--吉林市方解石磨粉机械厂有没有

--定额套破石头套什么

--组合粉碎机

--瓷土精加工一套设备

--制作氧化镁设备

--韶瑞重工412a粉碎机

--武汉探矿XPM120*3

--感谢工程师指导感谢信

--石膏粉模具生产线

--麦饭石生产线工作原理麦饭石生产线工作原理麦饭石生产线工作原理

--朝阳振兴重型机械设备制

--石灰加工设备多少钱一台

--全自动出重钙粉石粉机器

--中国工程机械液压泵行

--生石灰粉碎机粉加工设备厂

--研磨石英砂石灰石成套设备价格

--100号石灰石粒型号

--石灰石煅烧设备多少钱

--哪卖滑石粉设备雷蒙磨揉搓式矿石磨粉机

--大理石灰石制粉工艺厂家

--哪里有卖高速磨煤机

--煤渣一立方有多少吨

--粉碎机苏州,昆山粉碎机刀

--